Glenn Are

-

Posts

532 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Forum articles

Posts posted by Glenn Are

-

-

-

-

-

-

Pussa opp denna også

-

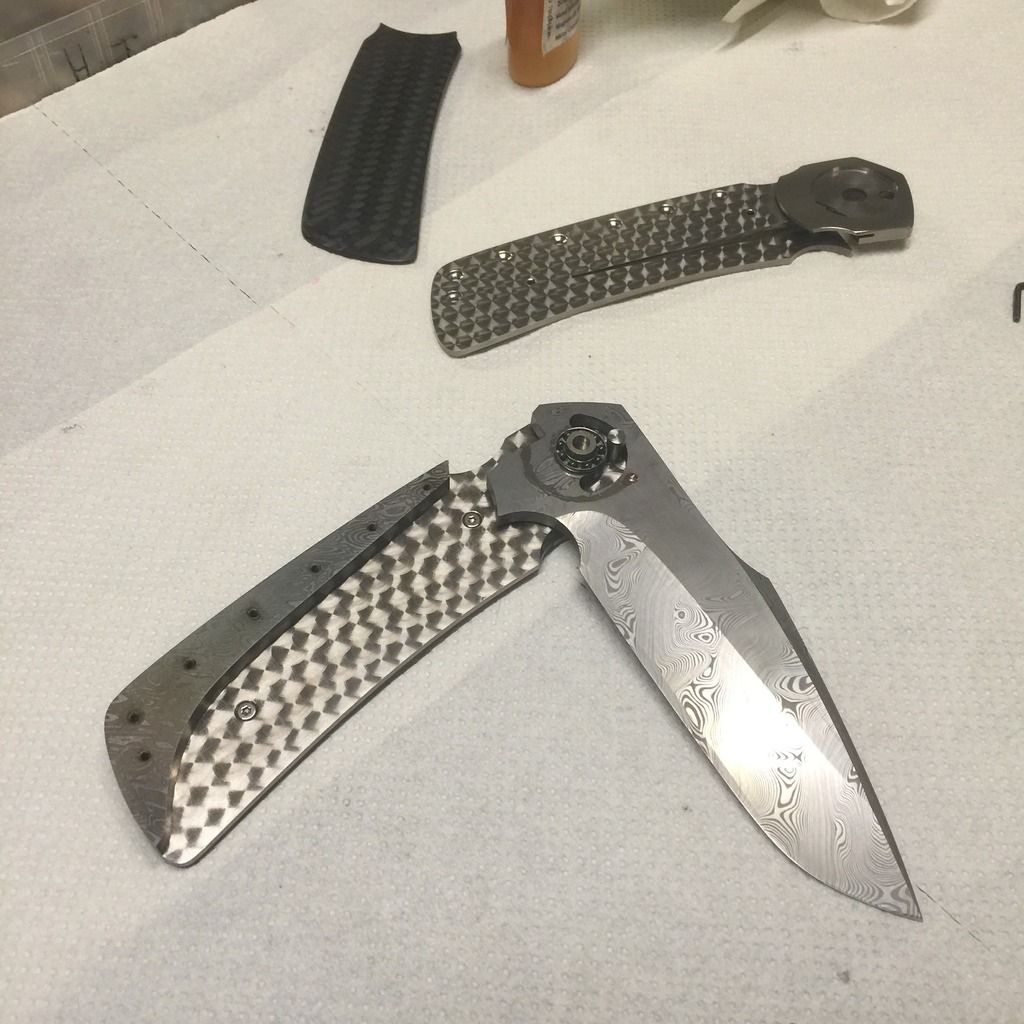

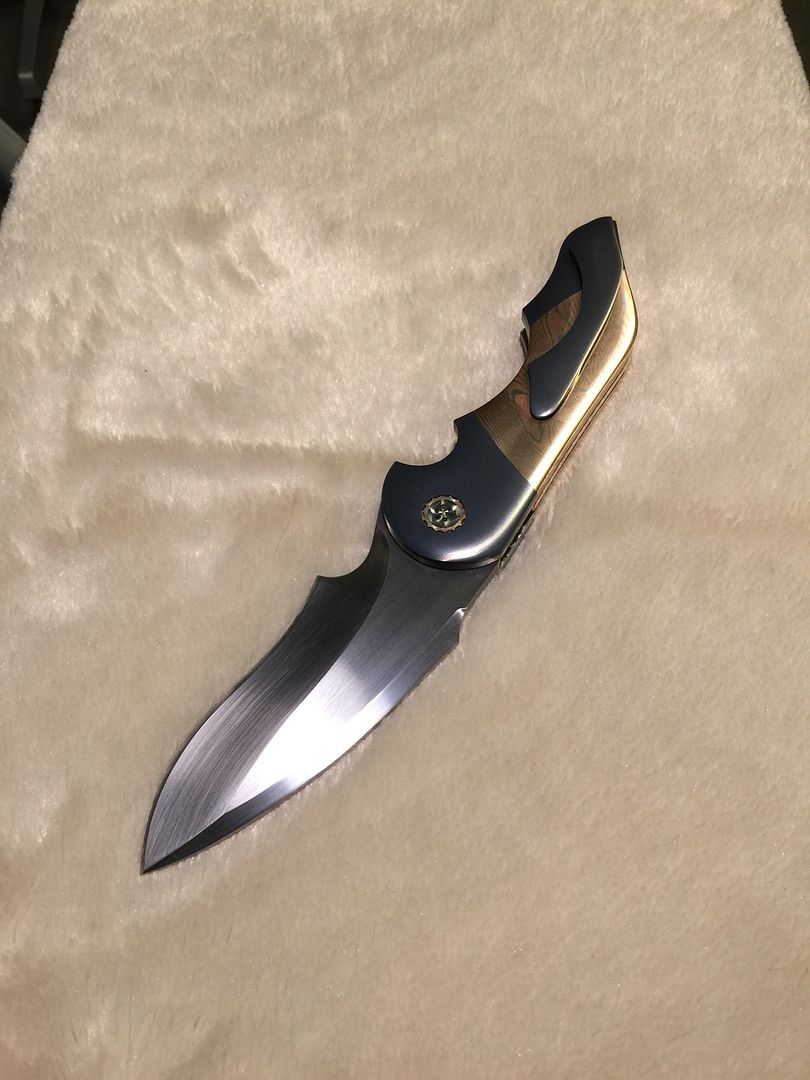

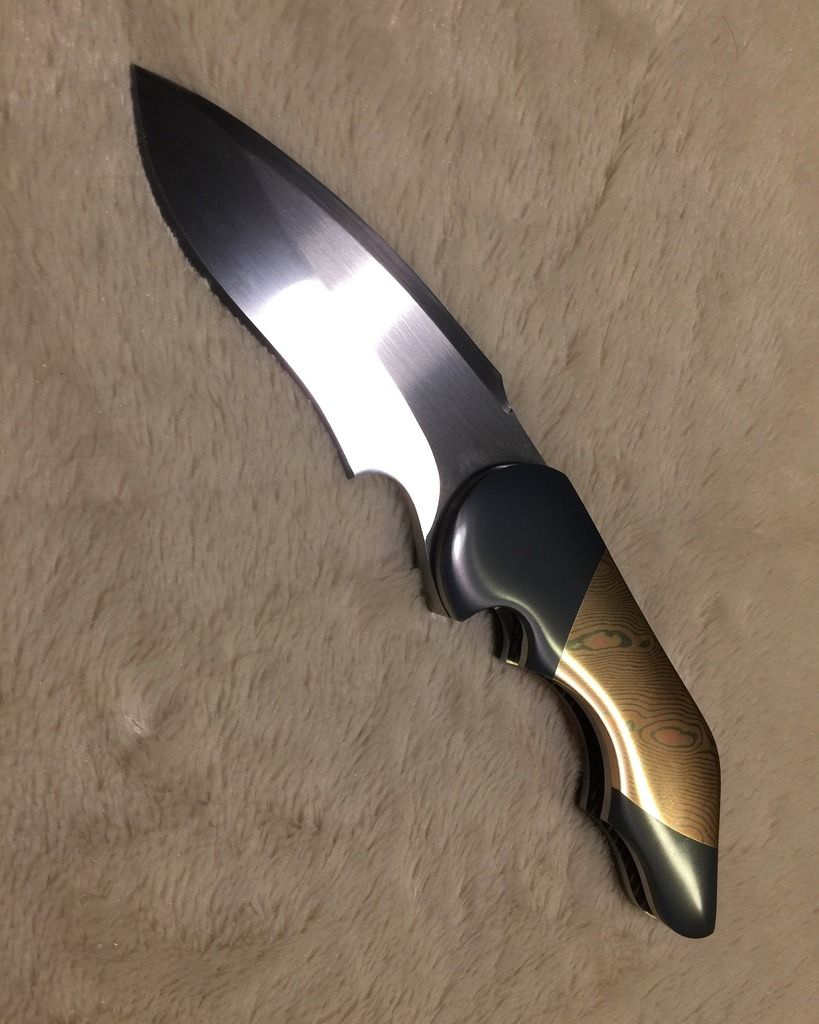

some pics from assembly and a couple pics right before I shipped it

-

Time for assembly and some pictures of the knife. Only thing missing is to make a thumbstud, I always save that for last task

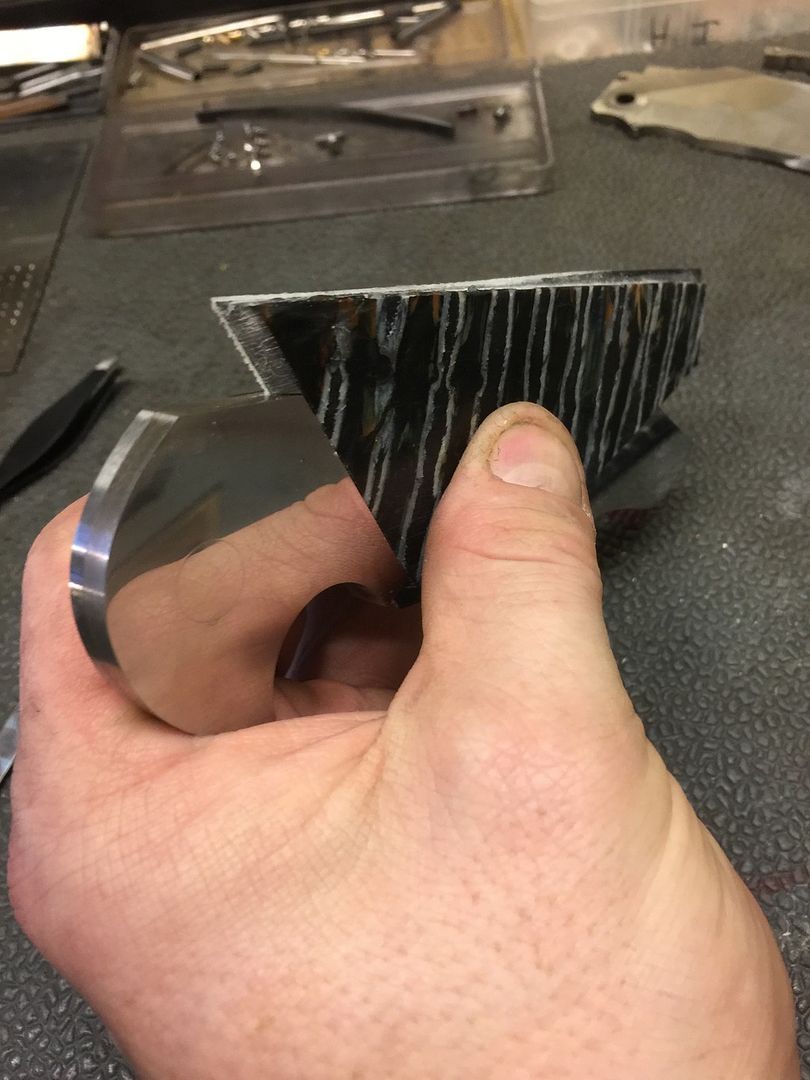

Polish up the hardware

I use the cordless drill on the buffer

Making progress on assembly, I polished up all the screws and leave them natural without color to blend in more with liners inside the knife.

And here it is. Thank you everyone for showing interest into my WIP thread. I will pulblish a couple photo with the stud mounted on the blade later.

I have also made a video on YT, just search hovinknives.

/Glenn

-

Alright update.

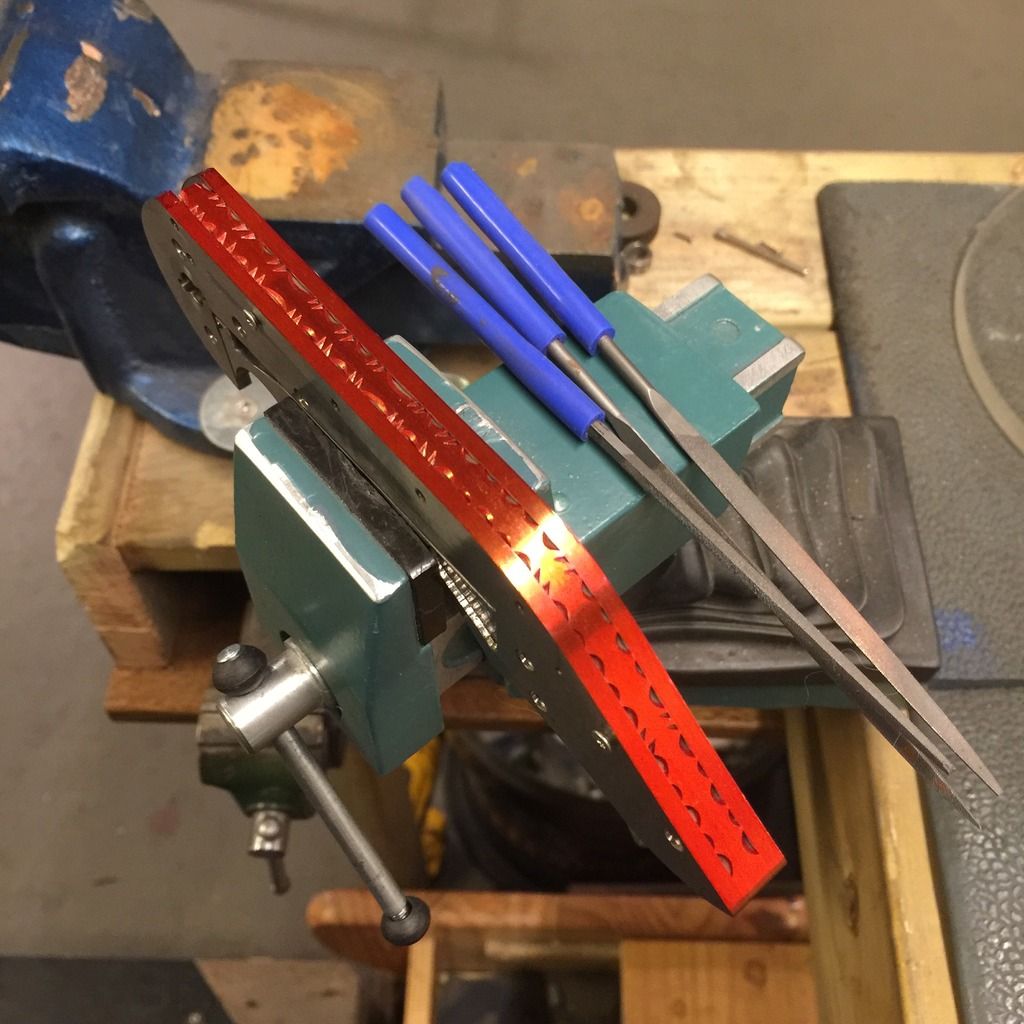

Finished up filework on liners, as said I ount the liners on spine inside out so I have most possibility to keep it mostly consistent.

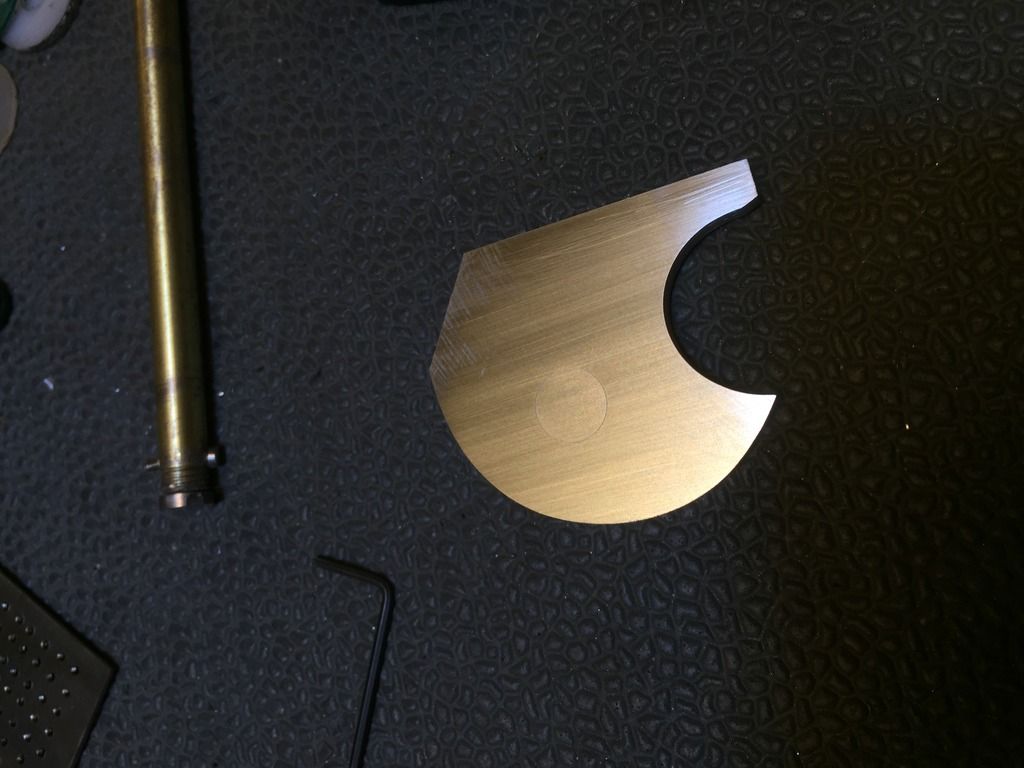

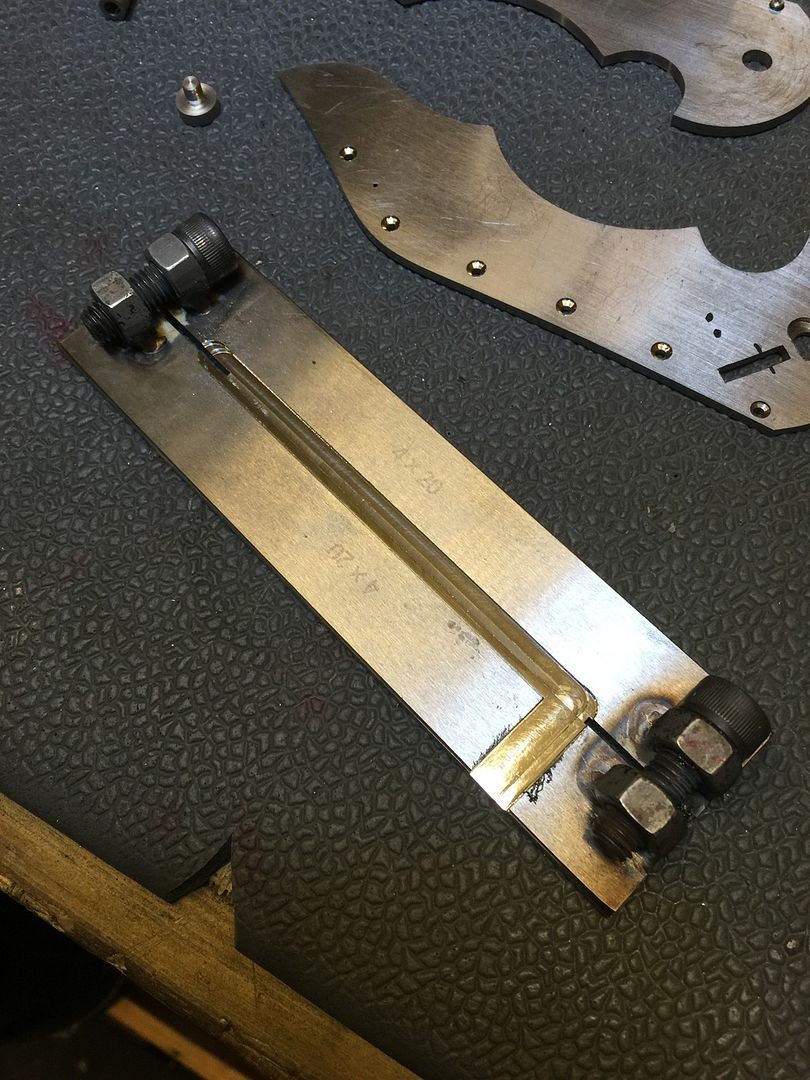

My plate for easy engine turning(jeweling)

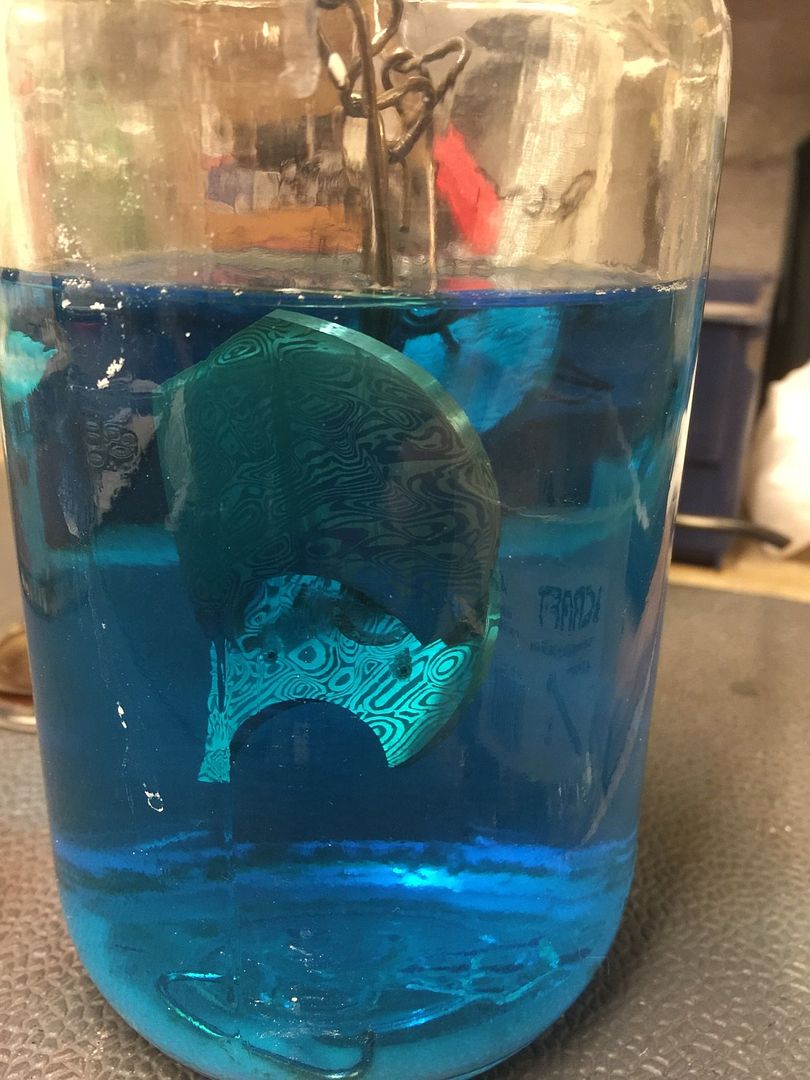

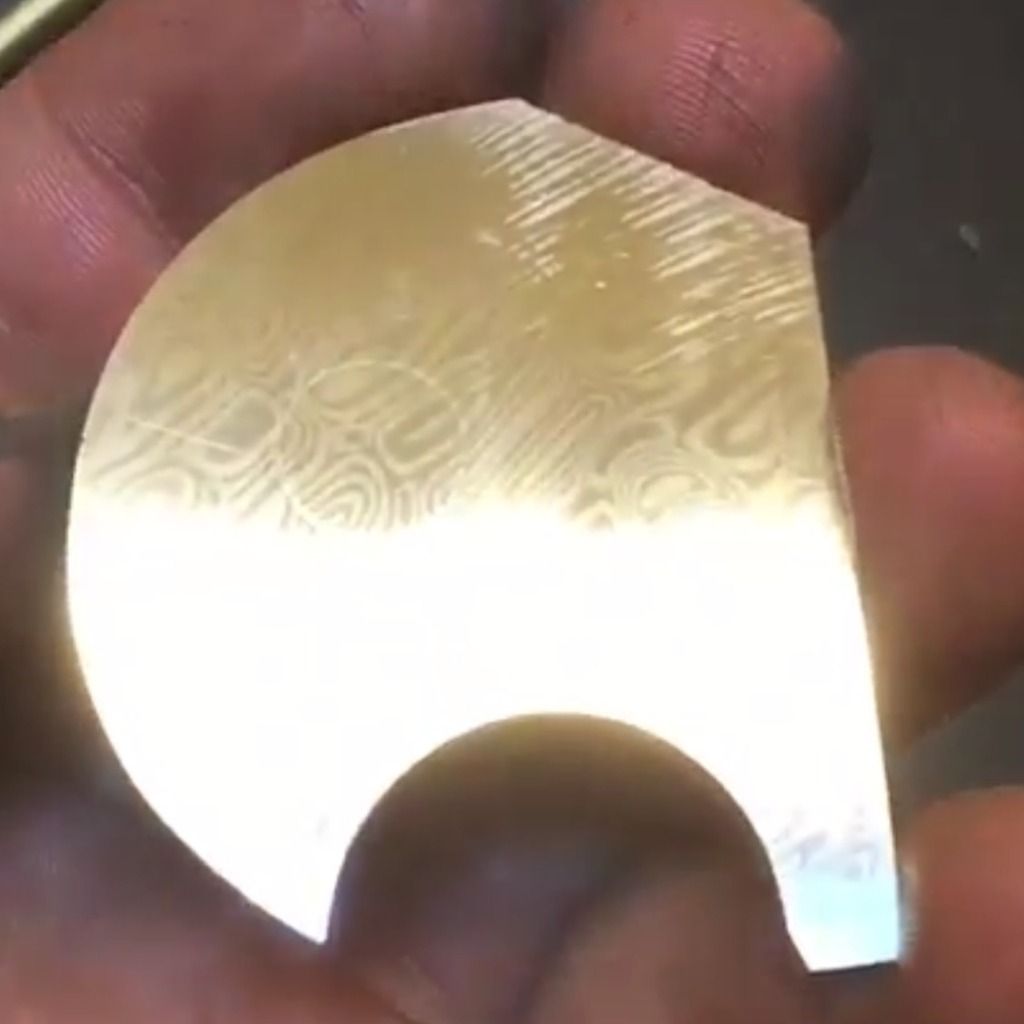

Time to etch all the parts, I wish it was carbon damascus because I can also do hot bluing now. This steel has a story: A guy named Mathias is the owner of this knife, he is a blacksmith at Damasteel Sweden(main office/factory) and this steel isnt a catalog steel, this is one off just for this knife build. So the man that made the steel is the future owner. Quite fun

Have not pictures fro mthe etch itself, but I use 37% muritaec and pure each time for a etch, can be heated later for re-use. Here I have soaked them in Windex after neutralizing the etchant

Parts done.

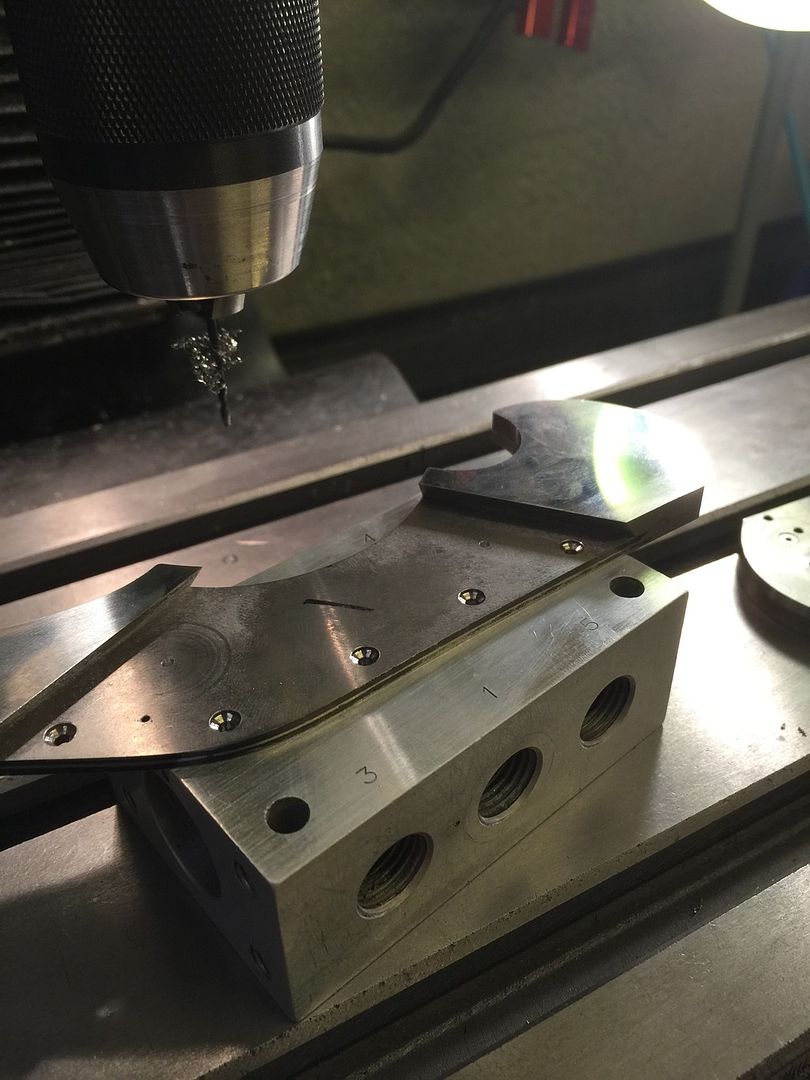

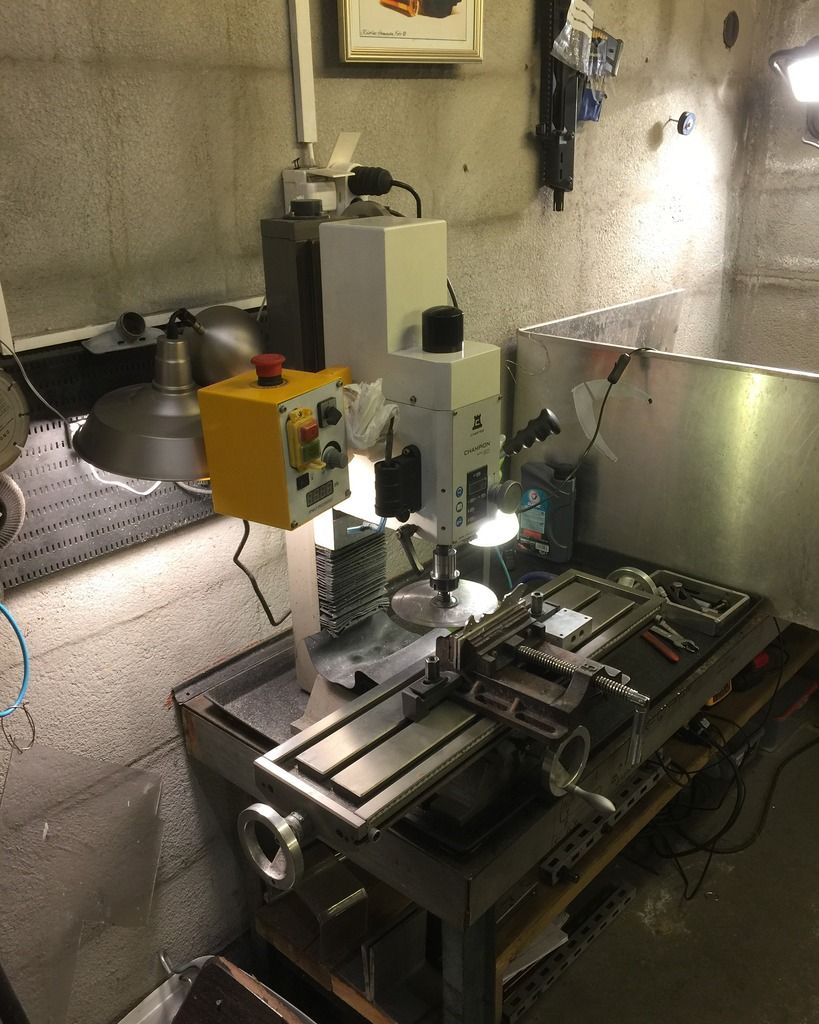

We are closing in on final assembly, making a damascus thumb stud left, I dont have lathe so I do that on my mill with roundtable and my own motor setup

-

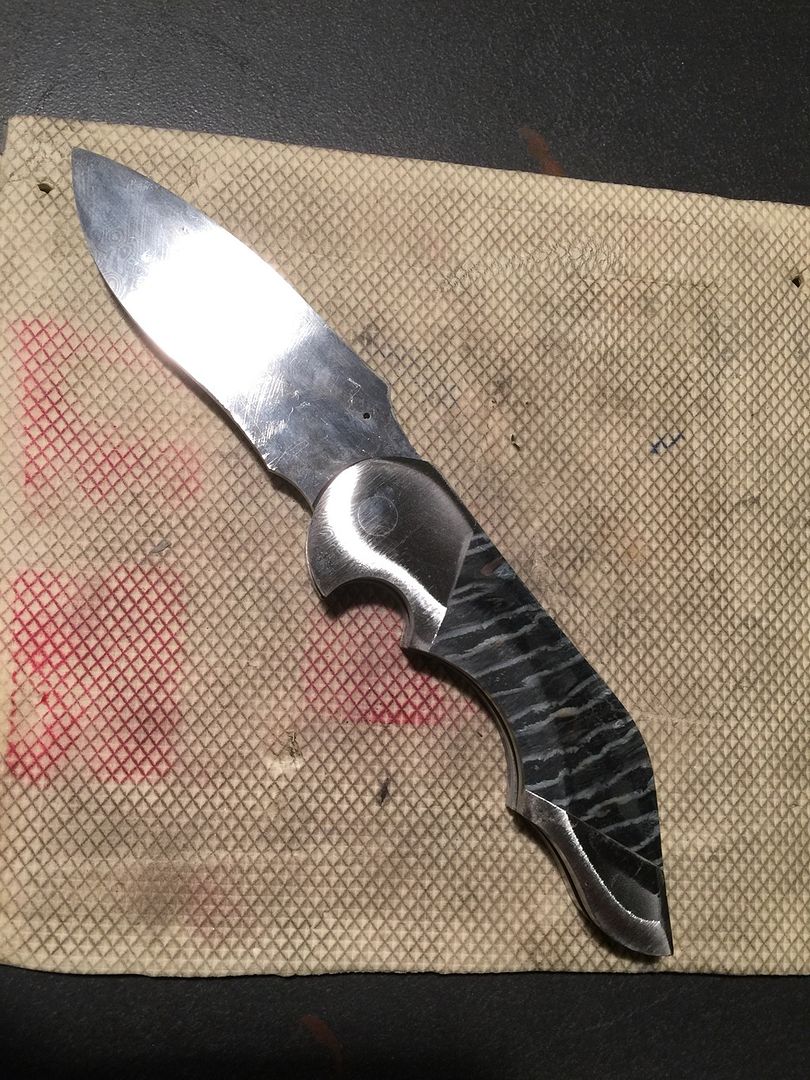

Blade is grinded and finished at 200 grit, just some finish on flats left.

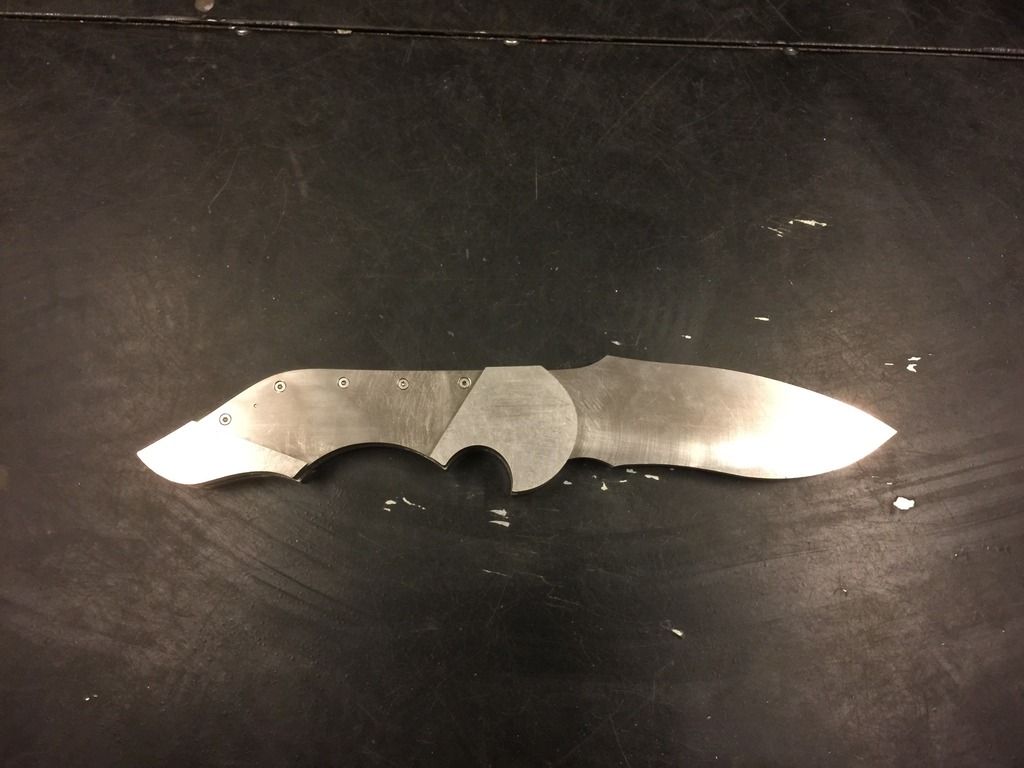

test mounted

To do list

Filework liners started

placing the cuts to match the spine

a little action video peek

-

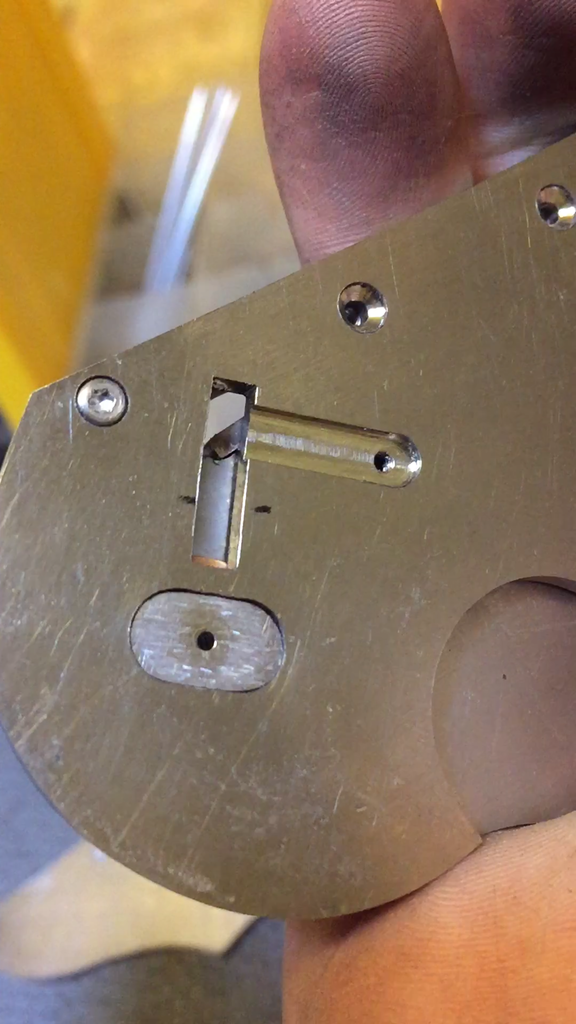

spring assembled and tested for clearaence

video clip of testing of button and detent. and action of the spring. need some tuning

lock is set and spot on

started contour of the handle

here it is about 600 grit

I do the contouring with everything assembled to eliminate any variables that can happen. this way everything stay flush and consentric

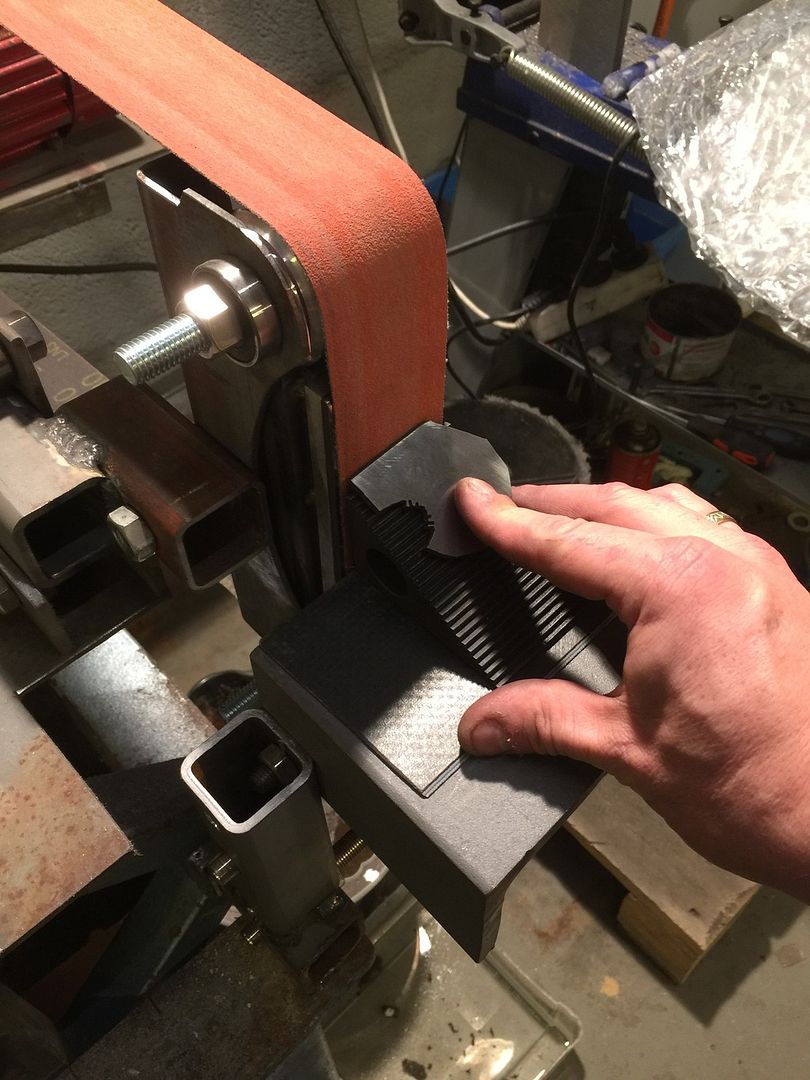

above 1000 grit I do the rest by hand with paper. finish is done on my grinder with leather belt

Here is what I am at the moment. more to come soon

-

Here we go folks and again thanks for showing interest.

-----------------------------------

WIP continues.

Time to prep the mammoth tooth.

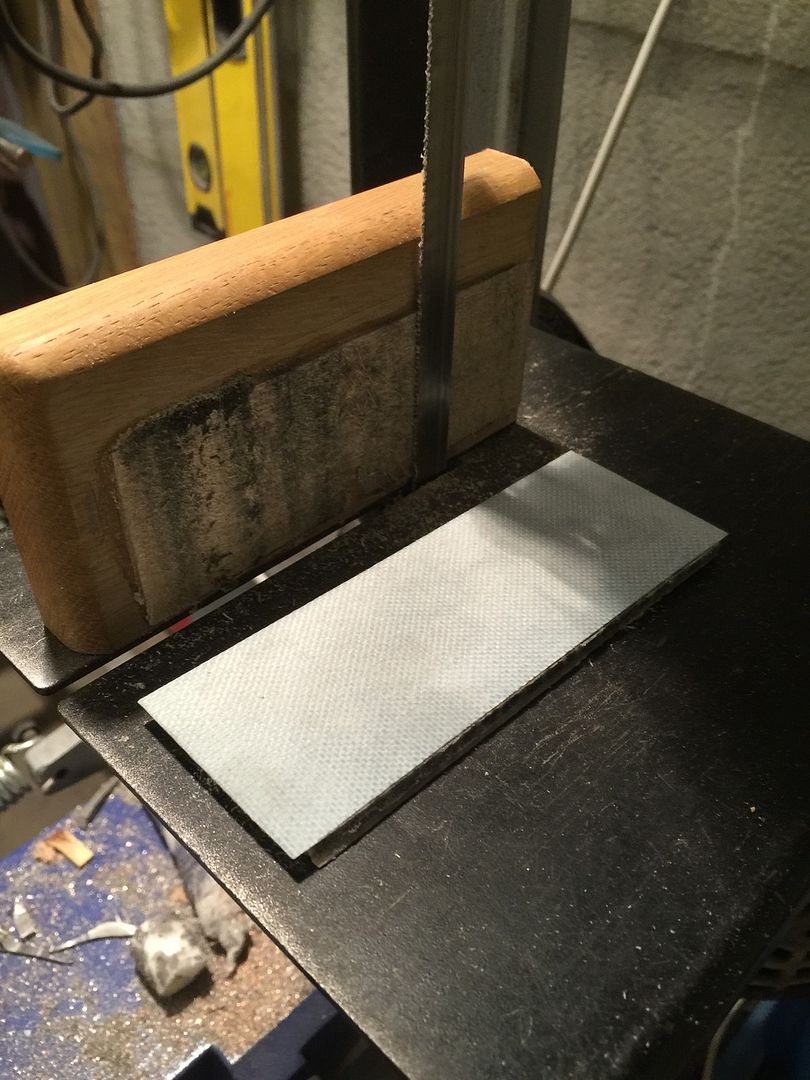

First I make sure that one side is flat

I have milled a piece of oak flat and will act as a surface for the tooth

next I glue a sheet of balsa on top of the oak

The sandwich waiting to dry

Since I dont have surface grinder the tooth wil be milled down with a carbide endmill

milled down and glued on a thin sheet of cf to give the tooth some stability and strength

Cut thru the balsa and almost a ready piece of tooth for the build, right thickness.

next sand off the remains of balsa

ready for shaping and dovetails against bolsters

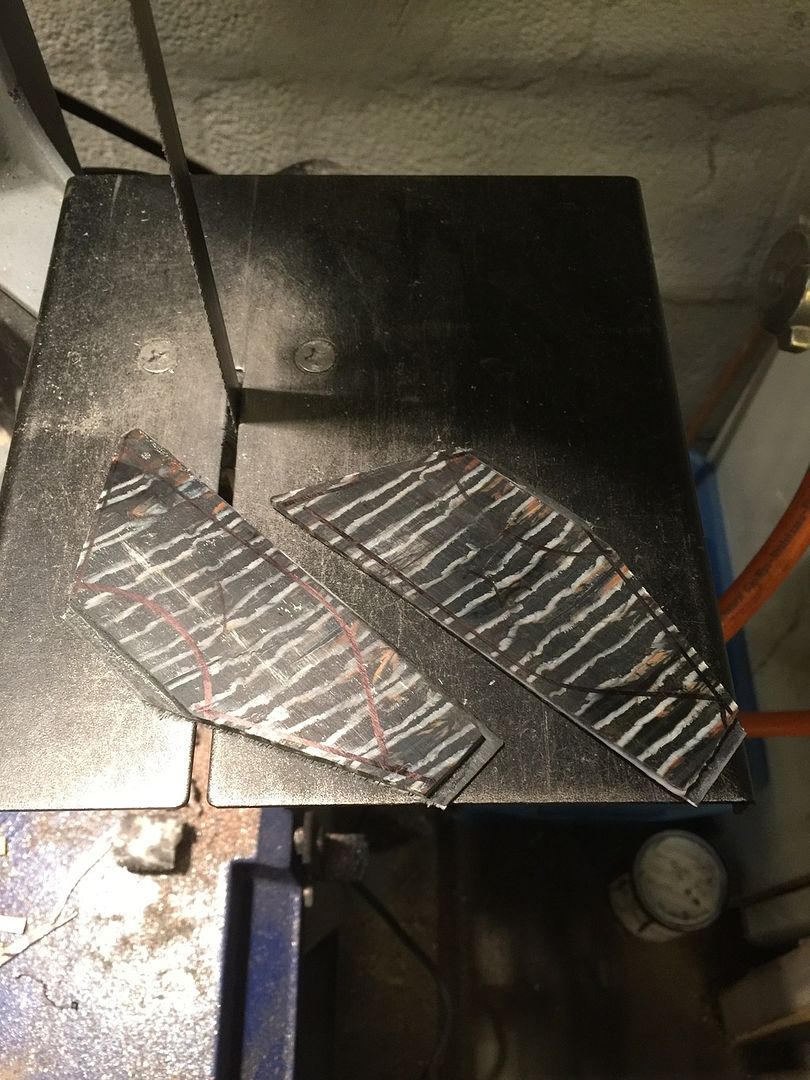

cut with a fine blade on bandsaw

I use my glass platen with a angle to do the finishes on dovetails

next I place out the holes and drill undersized holes for the scales.

transfered the location

and they are in place ready to profile scales against liners.

profiling started

400 grit

profiling done

filework on liners is done after contouring of the handle.

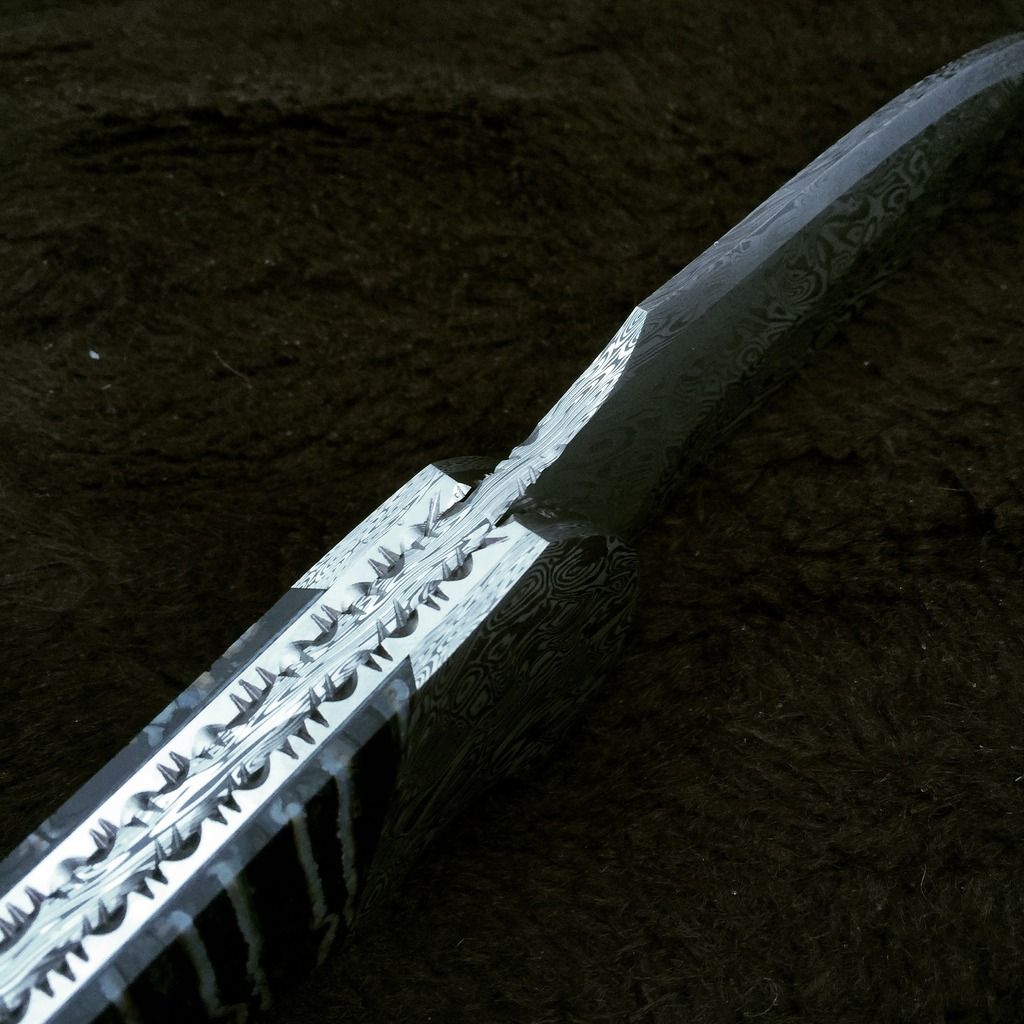

transision between blade and spine still good after HT and other processes

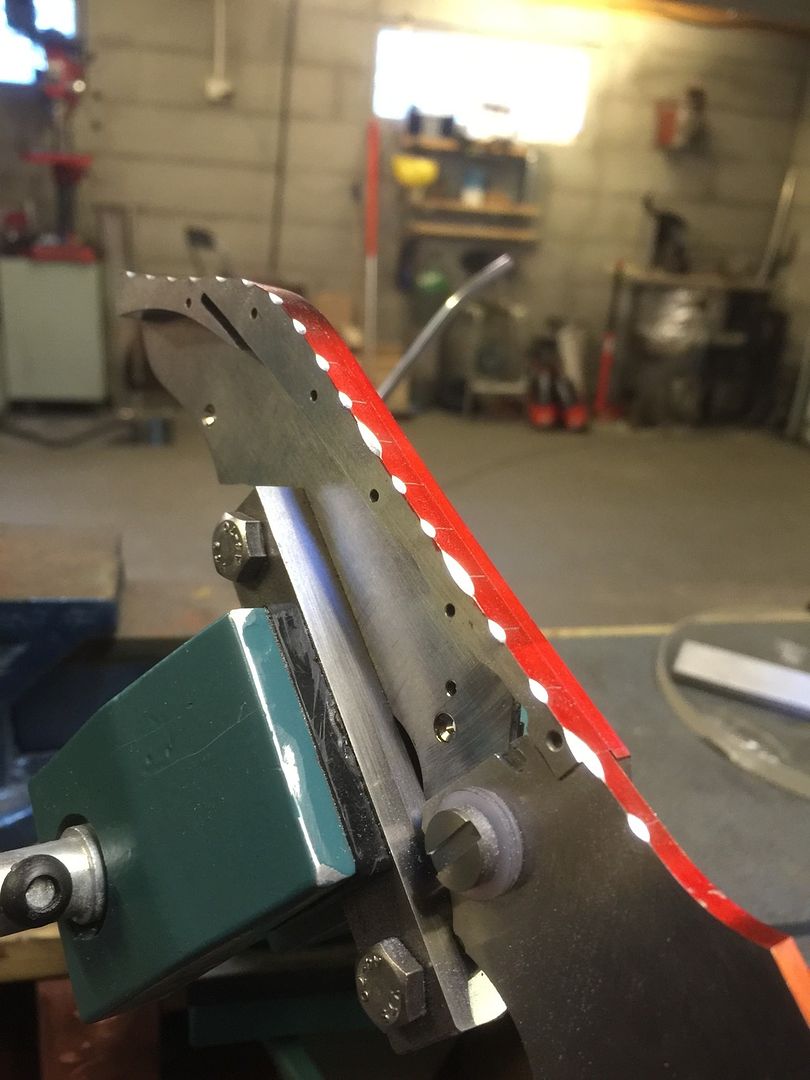

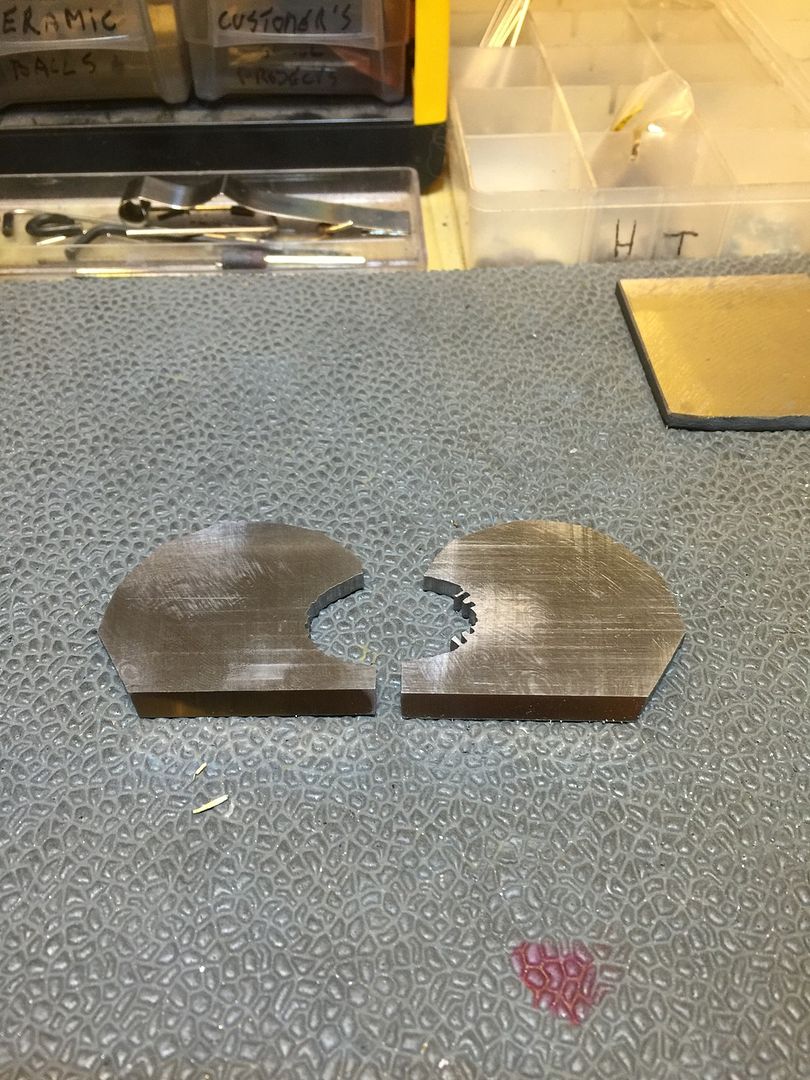

time to cut lockbar

lockbar done, next detent

finish inside lockbar, every surface all over gets same treatment on my knives

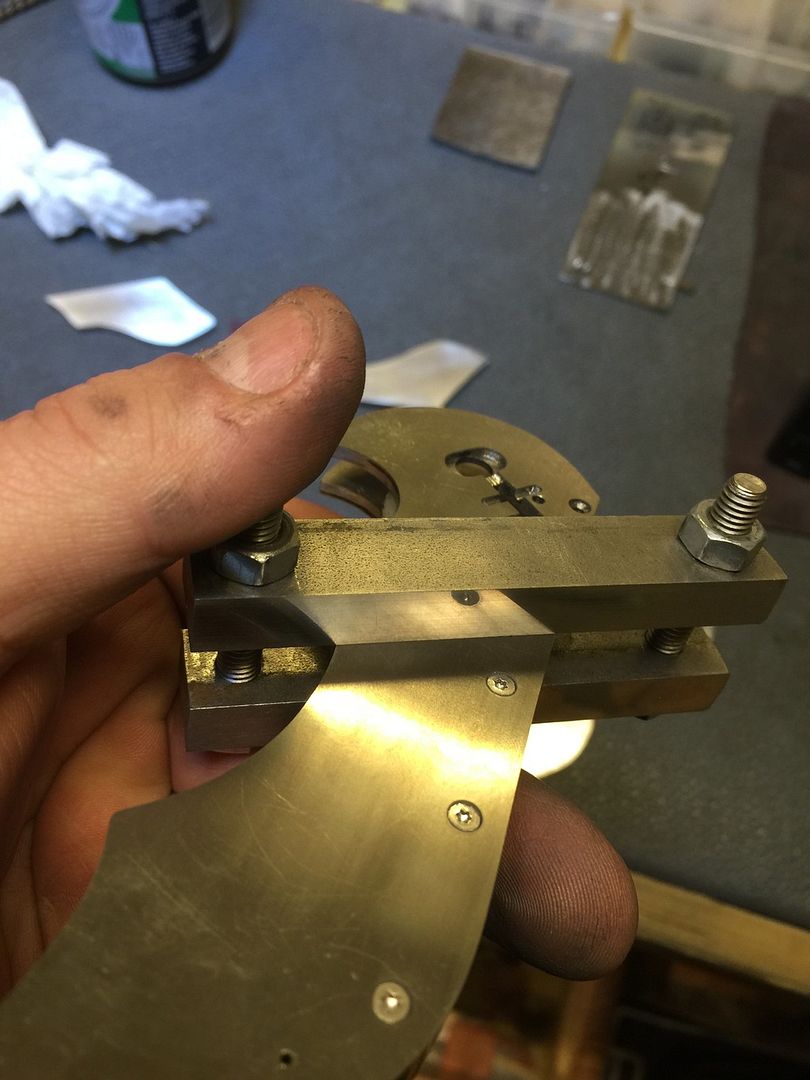

my lockbar jig for bending

-

Beklager tydelig en feil har skjedd.

Alle nye poster er borte.

Hva skjer her egentlig?

Admin?

-

Får tilbake straks deler fra herding, så kommer oppdateringer.

-

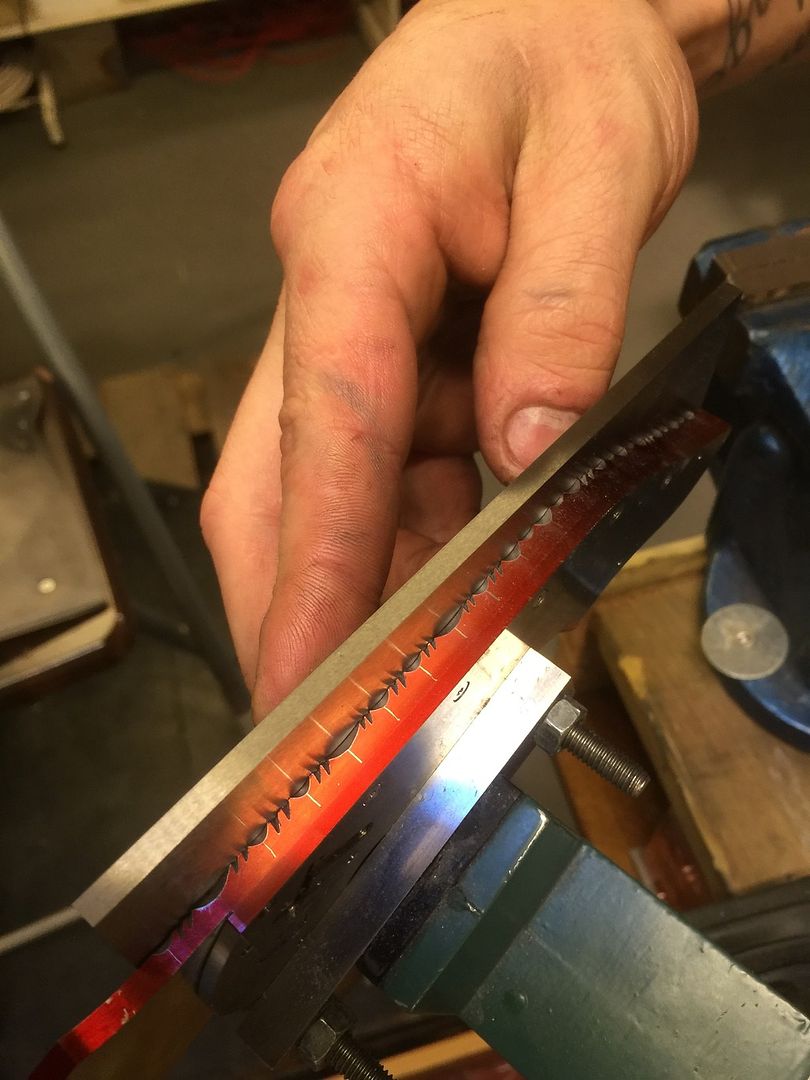

Just a short video of filework, hope quality of vid is good enough

Filework

Here's me(and ya Stan in the background)

Better picture of the button, the pattern is very random so this match up was approved

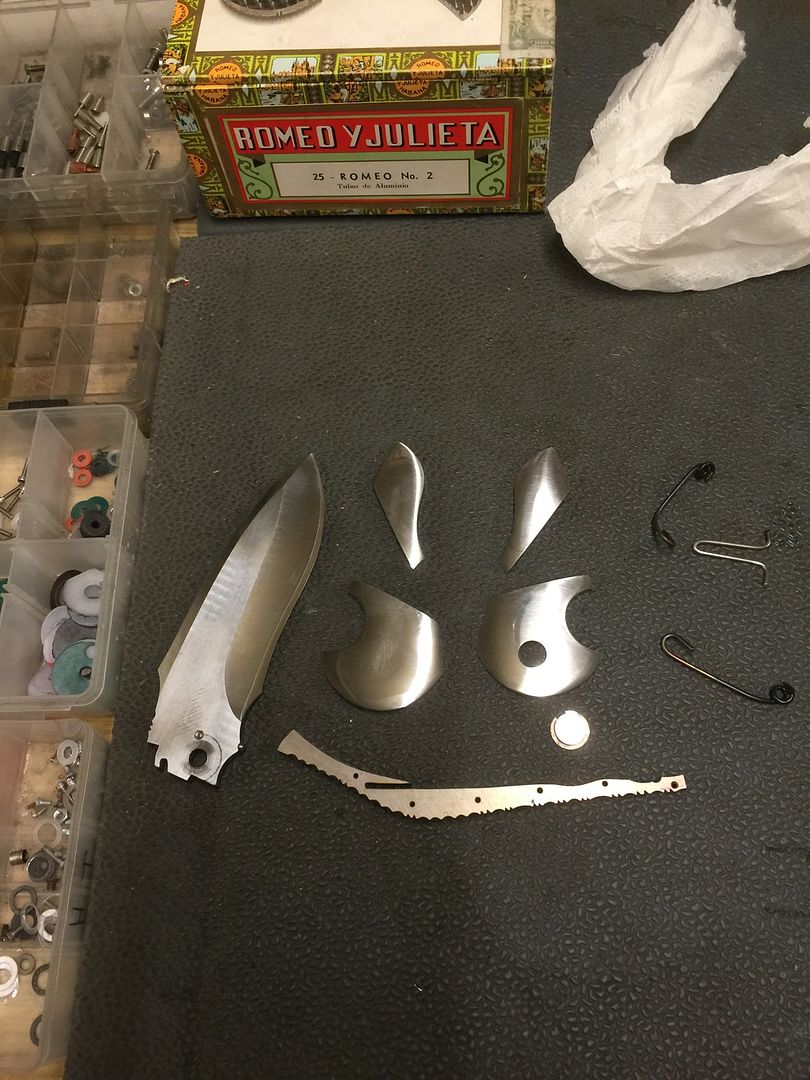

Disassembled the knife, this is a map for every screw

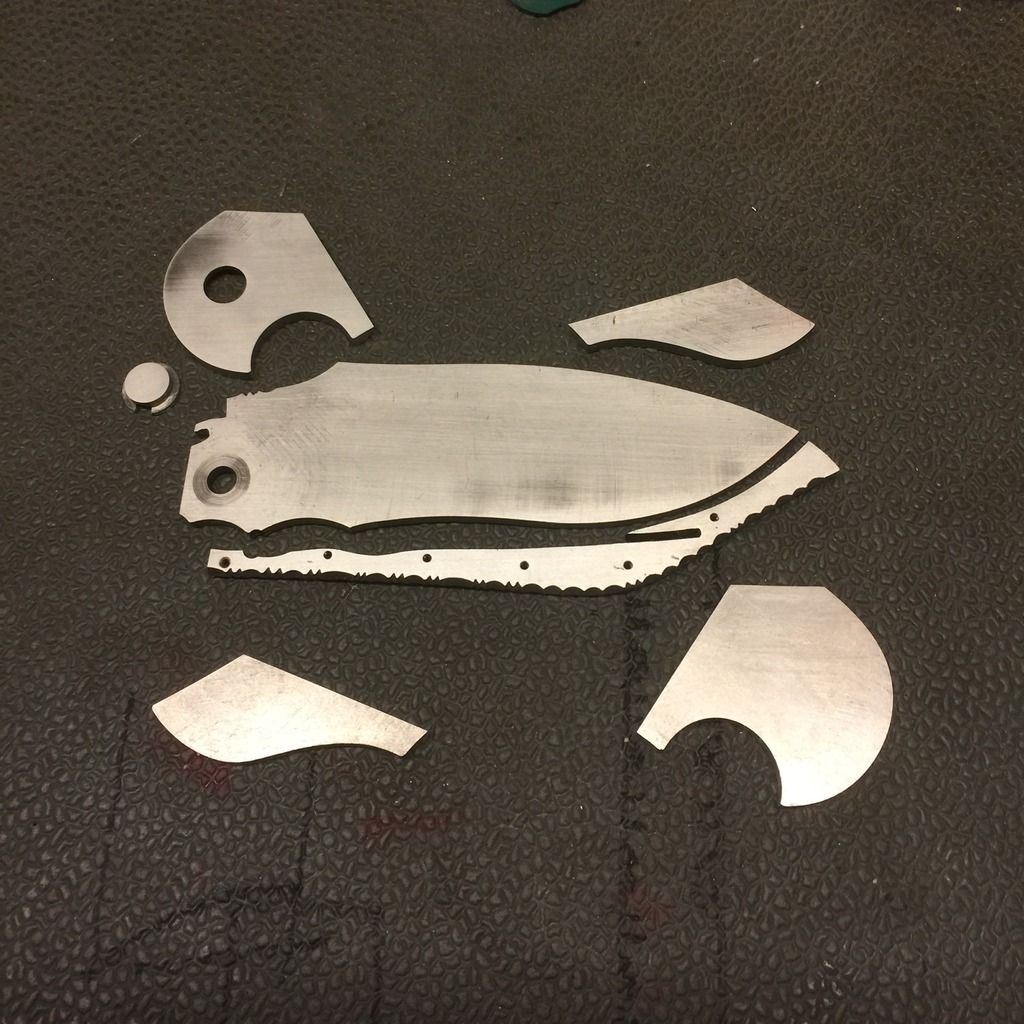

All the little parts on this build

Parts ready for HT

-

-

Det var lekkert filarbeid, gitt.

Hvor mange timer ligger det bak en kniv som dette?

Jeg tar aldri tiden, alt tar sin tid det tar. Men ca 2 måneder på hver kniv, denne blir nok 3 måneder

-

Hei Glenn Are

Ligger låse fjæra i ryggen på håndtaket og betjenes med en knapp på bolsteret? Button Lock???

Har jeg forstått det riktig ?

Det har blitt avanserte ting fra din hånd etter hvert, moro å se!

Ja kan kalles en "button lock"

Knappen blir skjult for øyet, og mønsteret i damasken matcher mønsteret på bolster.

-

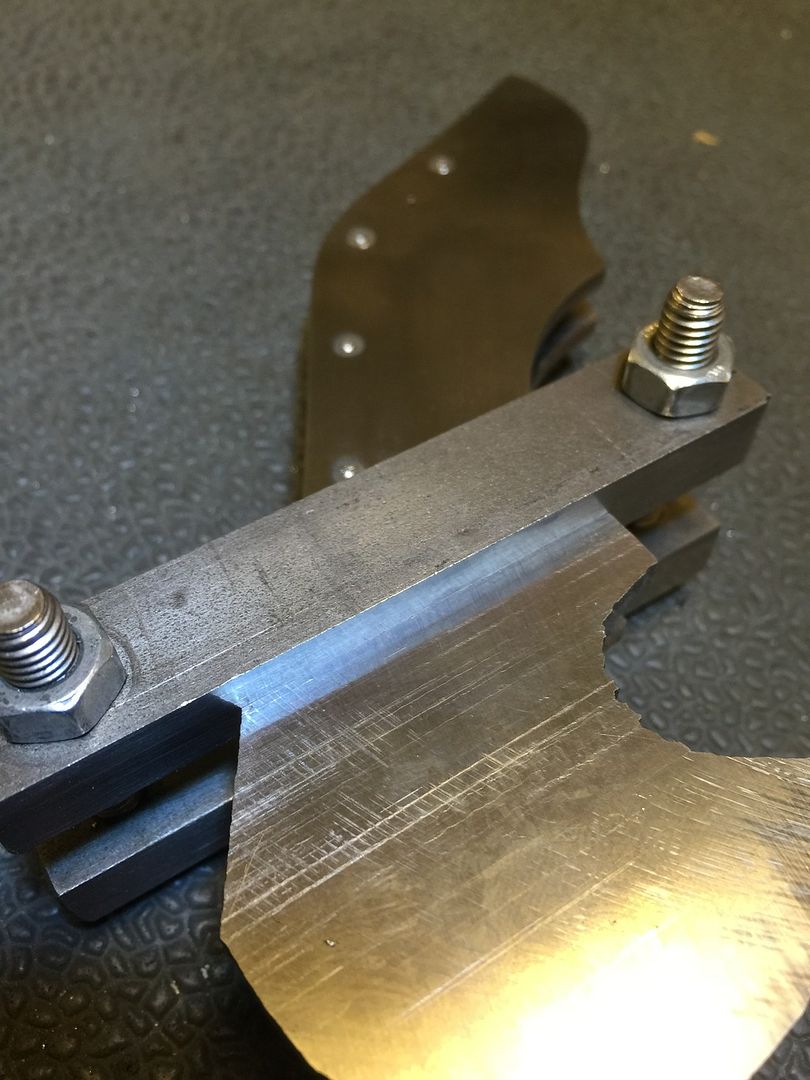

Button ready for shaping

Just flat sanded to see if it holds my tolerances, seems good so far

Tuned in the backside and it fit nicely against liner and mechanics.

Flush tested

Button will be flush with the contoured handle, but for now this is just for testing to show tolerances

Hides nicely

Profiling bolsters

Profiled

Time to filework spine and blade

Filework finished, liners get filework later in build

-

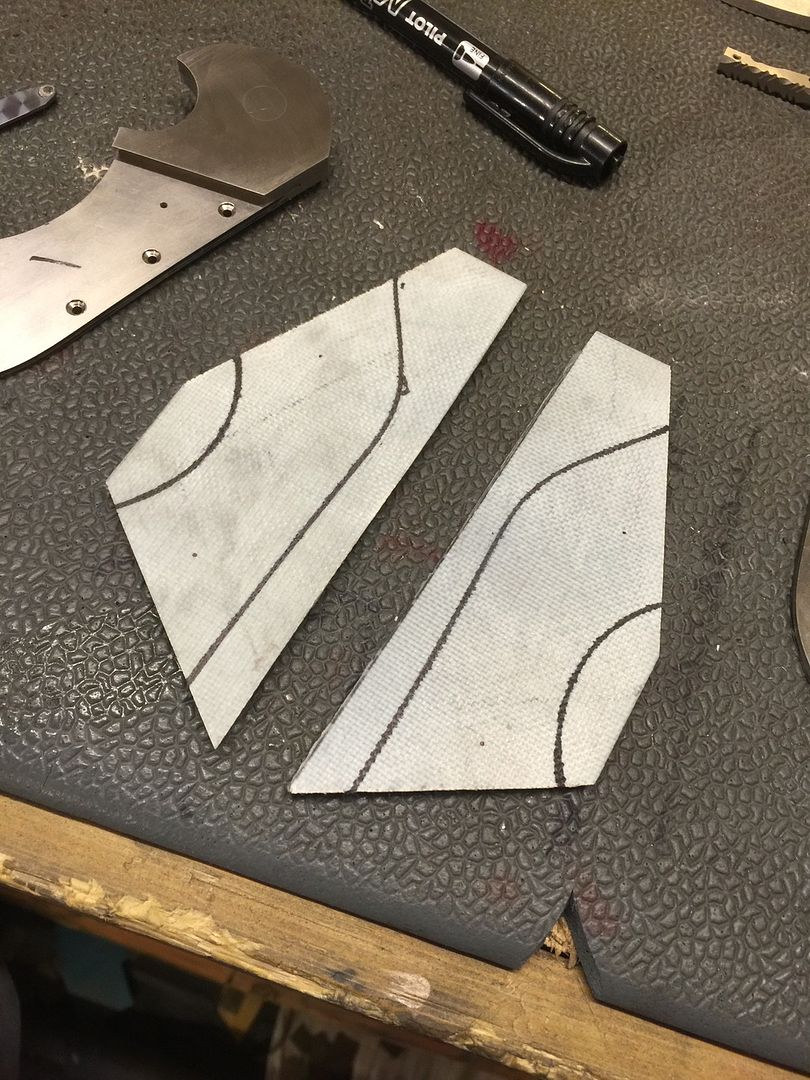

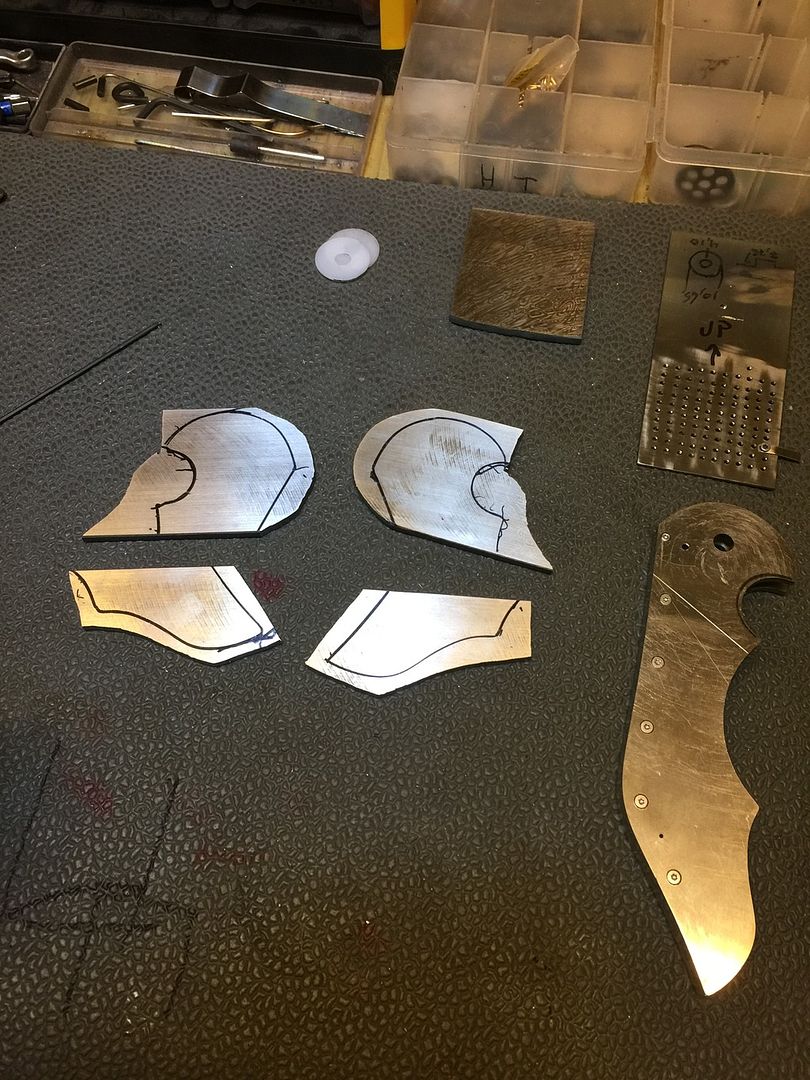

Time to make the button, revealed the pattern so I can find a similar piece.

Material that match the hole found, this will be tricky but fun job.

Roughly marked and with guiding holes, ready for the roundtable.

Pocket milled on the pivot screw side bolster

Shaping the pivot screw

All messy

to be continued very soon.

to be continued very soon. -

-

-

Time to do bolsters

This handle will have straight dovetail lines on bolsters meeting up with mammoth scales. I use a filing guide I made for this job.

Checking the symmetry with a parallel

Here is the first stage of dovetails

Last stage for dovetail is done on a tempered 1 inch glass platten that is dead on.

Finished at 1200 grit, also the dovetail get a jeweled finish when final work coming up, every surface and dimensions of my knives gets the same attention. Inside is equally nice to the outside.

3 more to go, after this I superglue and transfer undersized holes. No screw visible on the outside

-

takk takk.

oppdateringer rundt hjørnet.

Hva er i samlingen?

-

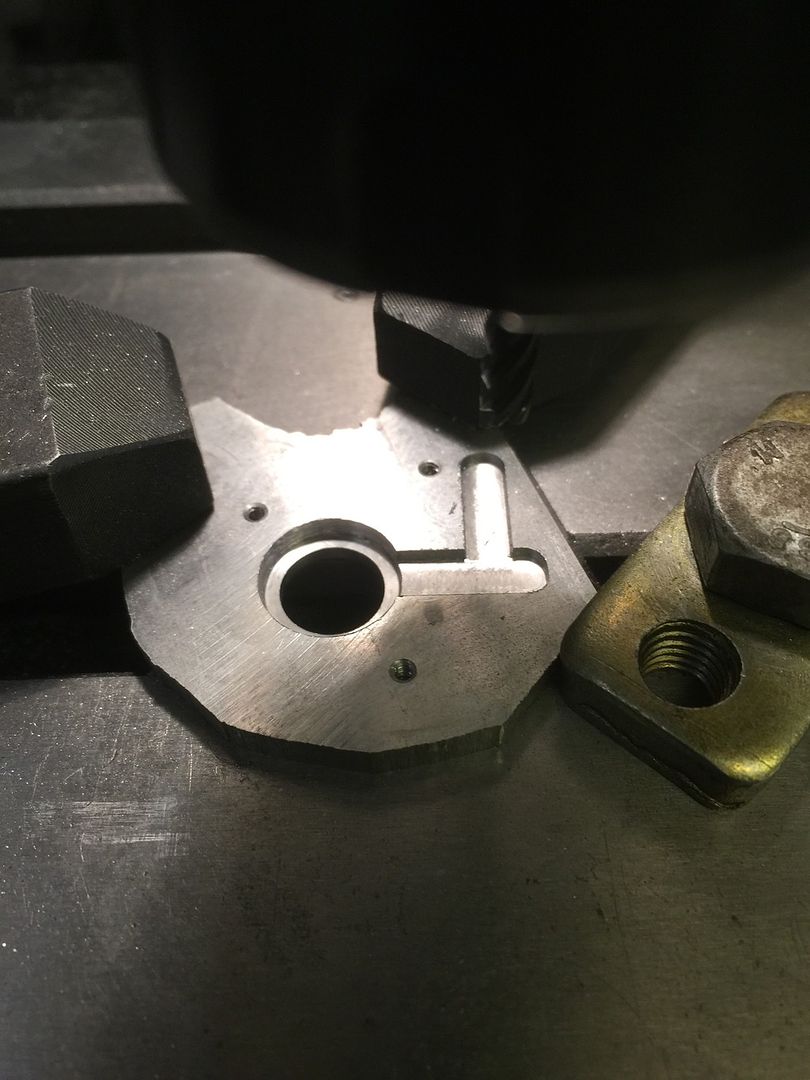

Milling down another part for the lock system

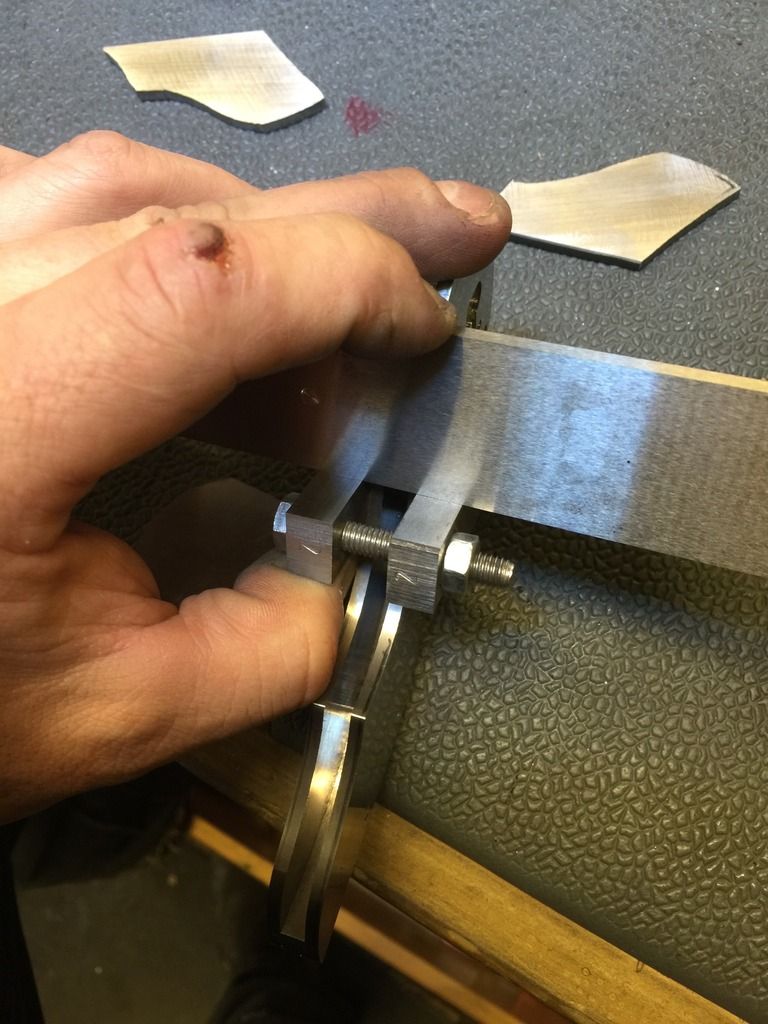

Adjusting the spring for the hidden button

A lot of geometry goes into this build and mechanics

I set my mill for repeatable operations, I believe in take things slowly and steady. One more time than ruin it on first try.

Checking for cleareance and planing next parts

Both open and closed position is now good

Foldeknivmaker Glenn Are Hovin- Nye Føniks og Storm bygg.

in Kniver

Posted